About

- Why Algae?

- Educational Resources

- People

- Photos and Vidoes

- Contact Us

This free course is designed to introduce students to the issues of energy in the 21st century – including food and fuels – which are inseparably linked – and will discuss energy production and utilization from the biology, engineering, economics, climate science, and social science perspectives.

This course will cover what algae are, why they are important, and why we are interested in them for both their environmental benefit, as well as their use for products. You will also explore the vast diversity of algae including the characteristics and applications of some of the main types of algae that are in commercial use today.

Lesson Plan by Cameron Coates and Tara Howell

This lesson plan was designed for a high school AP Environmental Science class in San Diego CA. The unit is focused on biomass energy with a particular emphasis on algae biofuels and is intended to teach students what biomass energy is, what the trade-off are for using biomass energy and what the current state of the art is for using biomass for energy. Our society is facing a number of serious challenges involving energy and today’s students should expect to see important decisions being made about energy in their lifetime. With a deeper understanding of the opportunities and challenges involved with biofuel and biomass energy students will be better equipped to make informed decisions about how they use energy in their personal and professional lives.

Researchers at Cal-CAB have studied best practices for growing microalgae and cyanobacteria at a large scale at the UC San Diego Biology Field Station. Below is a brief summary of the steps needed to grow algae from a laboratory plate to a raceway pond, and how to harvest the algae. More detailed information on the process can be found in a paper by Cal-CAB research Nathan Schoepp called System and method for research-scale outdoor production of microalgae and cyanobacteria.

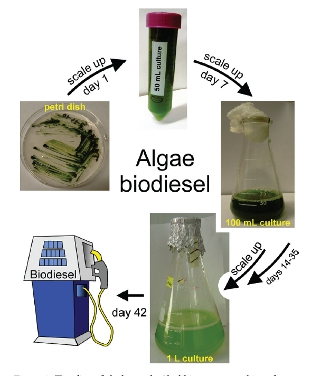

Below is a brief summary of the steps needed to cultivate and harvest algal biomass and convert it to a transportation fuel. More detailed information on the process can be found in a paper by Cal-CAB research Jillian L. Blatti called Releasing Stored Solar Energy within Pond Scum: Biodiesel from Algal Lipids.